OEM Supply Roll Up Door Sizes - Roll Up Door Forming Machine – Bestar Detail:

The Roll Up Doors or Roller Shutter Doors production line mainly includes 3 machines: Roll Forming Machine, Seaming Machine and Pakcing Machine, which work together to make complete Roll Up Doors or Roller Shutter Doors.

The complete Roll Up Door or Roller Shutter Door Forming Machine includes decoiler, main machine, automatic controlling system and run out tables. Our machines are equipped with automatic controlling system. We simply program the quantity and length we need in the computer and the machine will produces it automatically. The machines are easy to operate and run stablely.

Roll-Up Doors, Constructed from 26ga sheets of steel roll formed with integral grooves by Roll Forming Machine, are hemmed by Roll Up Door Seaming Machine together to form a continuous sheet guided vertically by roll formed guides.

Specifications:

(1) Feeding Material: PPGI/PPGL coil sheet

(2) Material Thickness: 0.40-0.55mm

(3) Speed (Adjustable): 10m/min

(4) Power: 7.5KW, 380V

(5) Roller: Φ75mm, SUJ2 with hard Chrome coated, 22 rolls

Standard Features:

Long Service Life: Rollers made by #45 steel with hard chrome coated

Digital Control: Mitsubishi PLC with touch screen. Friendly man-machine interaction. Simple to learn and easy to operate.

Automatic Operation: Once you set quantity and length of curtain sheet, machine will produce it automatically.

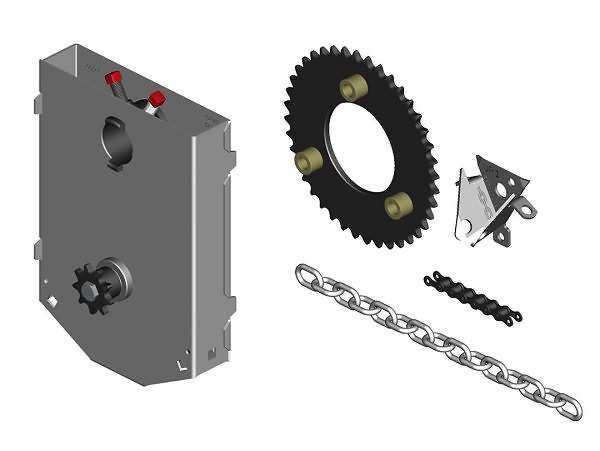

Product detail pictures:

Related Product Guide:

Our progress depends around the innovative machines, great talents and consistently strengthened technology forces for OEM Supply Roll Up Door Sizes - Roll Up Door Forming Machine – Bestar, The product will supply to all over the world, such as: Casablanca, United States, Macedonia, We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can offer the most competitive price with high quality,because we are much MORE PROFESSIONAL. You are welcomed to visit our company at any time.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.